TAT Talks, Episode 1: Must-Have In-House Aviation Maintenance Capabilities

What in-house aviation maintenance capabilities should you ask your vendor about, and why is it important that you know about them?

In an aviation maintenance facility, capabilities make a world of difference when it comes to time saved and quality of work.

Donnie Loflin, the TAT Piedmont Senior Director of Account Management, talks about the must-have in-house capabilities for any aviation maintenance vendor.

Why are in-house aviation maintenance capabilities so important?

Cost is less important when looking at Machining Plating and Grinding (or, as we call it, MPG). What you are looking for is peace of mind that your parts are in good hands, that they will be delivered on time with the highest quality, always.

Having most processes done in-house means that, depending on the part, you can save up to 2-3 weeks’ service time, if not more.

We have many customers who require multiple processes to repair their part. They appreciate the fact that they are able to have them all done in-house, without having to subcontract to multiple vendors.

Did you know…? In-house capabilities help mitigate additional freight time, which could increase the lead time for the completion of your part.

What are the aviation maintenance capabilities a vendor should offer?

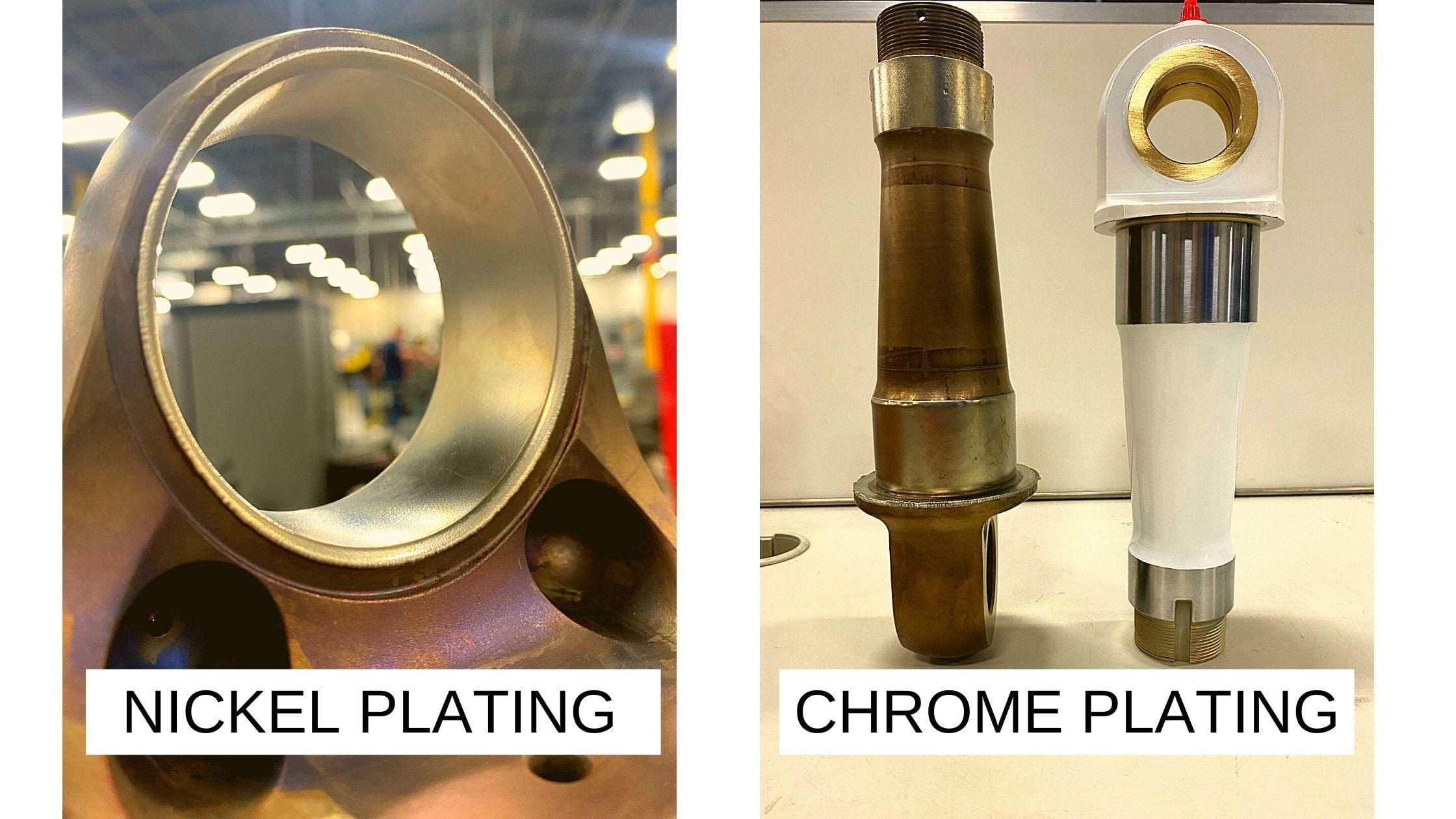

Plating shop

TAT Piedmont’s plating shop

An in-house plating shop ensures that you get access to a large variety of plating services, including Chrome, CAD, Nickel or Anodize. Some parts require both Chrome and Nickel on different areas of the part; having all these capabilities available in-house ensures a faster turnaround time.

A plating shop is used for various applications in aviation maintenance to protect the parts from corrosion. It is used in repairs as a layer of protection. Over time, these parts deteriorate and need to be replated and reprocessed.

Corrosion removal

A vital player in a plating shop is the use of the Expandable Tank Size. It is a versatile capability that can go up to 8ft, depending on the required plating process.

The TAT Piedmont plating tank

A well-equipped plating shop can decrease turnaround time, sometimes by weeks (depending on the part being worked).

One of TAT Piedmont’s landing gear customers, who was previously working with a different plating vendor, used to have their parts sent to multiple vendors for these processes. The turnaround time was not satisfactory; the entire process was time-consuming and was resulting in lead times that could last up to several months.

What is worse, the customer could not set realistic time frames for their own internal processes. This was creating constant frustration.

This customer eventually came to TAT Piedmont. They were able to find in TAT Piedmont the reliable vendor they needed, which could provide them with all the in-house plating capabilities they required. Now, their parts are being delivered within two months for all required plating processes. This gives this customer a time frame they can work with to organize their own internal processes.

As a result, this particular customer has been a regular, returning customer for the past eight years.

Machining

A machine shop on site is a must-have aviation maintenance capability. It can accommodate the plating shop and ensures accurate measurements (such as high accuracy in removing imperfect material).

There are different types of machining capabilities: CNC machine, plating and grinding, turning lathes and mills. Most of these machines deal with removing material to the required OEM specifications.

At TAT Piedmont we have between 10-15 different machines which help us remove material to different extents and on different parts. In addition to manual mills and lathes, we also have two CNC mills, one CNC lathe, one CNC grinder, and one GAP bed grinder.

The highlights of our shop are the HARDINGE CONQUEST V1000 machining center CNC machine, HAAS VF-3D and SUPREMA 1000 Jones & Shipman cylindrical grinding machine.

HARDINGE CONQUEST V1000 machining center CNC machine

Did you know…? At TAT Piedmont we can give you accurate lead time estimations based on the processes you require and on the aviation maintenance capabilities we offer, so you can better organize your internal processes. All parts are delivered on time, according to the specified lead time, always.

Specialty Services

Additional in-house specialty services contribute again to decreasing lead times. At the same time, they ensure a better repairs/maintenance process with increased accuracy.

Shot peen

TAT Piedmont Shotpeen

Gears, gear shafts and splines go through this process.

At TAT Piedmont, we offer Roto peen and Shot peen. When requesting this service from TAT Piedmont, you will be required to provide us the following information:

- The type, size, and hardness of the peening media to be used

- The desired intensity (how hard the component is to be peened)

- The amount of coverage (peen once, twice, etc.) required

- The specification to be used, e.g., AMS2430

- Clear instructions regarding the specific areas required to be peened, optional areas, and any areas where peening is forbidden, and the part must be masked

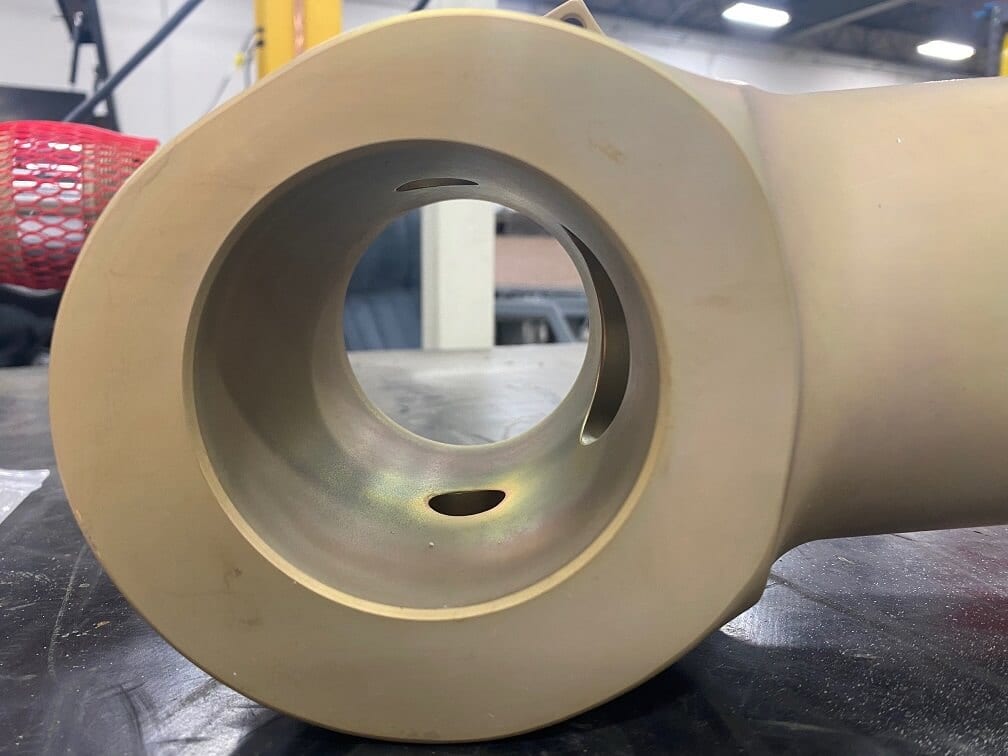

Paint booth

The inside of the paint booth, which can accommodate parts as big as aircraft wings

Our paint booth is 12x9x28ft, which allows us to accommodate parts as large as aircraft wings. With our paint booth, we can paint and cure parts up to 169°F. The size of our paint booth allows for more efficiency, increased capacity and decrease cycle time by about 300%.

NDT

NDT stands for Non-Destructive Testing, giving the ability to check the integrity of a component without causing damage to it.

Why is NDT important to the aerospace industry? In the aviation industry, things can get expensive fast. NDT is a good tool to ensure the safety of parts to be able to use them again and in this way, reduce cost.

Are there different types of NDT services? Yes, and TAT Piedmont offers Penetrant, Magnetic Particle, and Eddy Current aviation maintenance capabilities.

NDT Differences:

- NDT Penetrant involves applying penetrant, rinsing after dwelling in penetrant, drying, applying developer, and inspecting with a UV light after developer dwell time. Defects of parts (cracks, for instance) will hold penetrant if not over-rinsed. Since our penetrant is fluorescent, inspecting with a dwell time will bring the penetrant to the surface at the defect. Inspecting with a UV light in low light will cause the defect to glow. Observation: all defects must be open at the surface when using penetrant.

- NDT Magnetic Particle involves magnetizing parts directly after applying a mixture of mag fluid and magnetic particles. Defects (like cracks) will create magnetic poles which will attract the particles in the mixture after being magnetized. Since we use fluorescent particles, the defects will glow under UV light when inspecting. Observation: all parts must have the ability to be magnetized when using mag particle.

- NDT Eddy Current uses induction to test parts. When an electrical current is applied to a coil, the coil will develop a magnetic field and an electric current to a conductor if placed near the coil. The current to the conductor (or test piece), will be in a circular motion (sometimes called “eddys”, which means “whirlpool”). A probe with a coil or coils is used to test parts. It is connected to an analysis instrument that will interpret and amplify the signal to a visible display. Defects usually show a bigger signal on screen. Observation: parts must be made from metal to use eddy current.

What are the benefits of having NDT on-site? You can save time and money. If we had to ship parts to another NDT lab, the cost would add quickly and time waiting on shipping would add up as well.

What certifications do we have at Piedmont to do NDT? TAT Piedmont is NADCAP certified in NDT and we also have a level three on staff NADCAP certified specialist, which allows us to meet almost any OEM requirement for NDT services.

Now that you know all about these aviation maintenance capabilities, you also understand why it is important to you, as a customer, to have them all done in one place. In the aviation industry, time is of the essence. Therefore, when you know that you can save tremendous amounts of time by having all these capabilities provided to you, you get peace of mind that you will always be on top of your game.

What should you do next?

Next time you are shopping for Machining Plating and Grinding services, make sure you ask your vendor about the in-house aviation maintenance capabilities they offer.

Challenge us! If you have a project that is off the manual, have a question about specific aviation maintenance capabilities, or a specific issue with a part, we encourage you to send Donnie Loflin a message about it. Simply get the conversation started, he will surely assist you with your request!

MORE NEWS

-

December 14 2020 Blog

TAT Talks Summary: Four Aviation Maintenance Experts Talk About Machining Plating and Grinding

-

November 30 2020 Blog

November 30 2020 BlogTAT Talks, episode 5: Aviation Maintenance Certifications, Can...

Are you looking for a specific aviation repairs and maintenance...

-

November 16 2020 Blog

November 16 2020 BlogTAT Talks, Episode 4: Done-for-you Engineering Support Solutions...

Do you have a part that (you think) is beyond repair? Do you need a...